-

-

Clay Brick

Range using recycled bricks

-

Faux Stone

-

Natural Stone

Range using real stone

-

Faux Concrete

Range using faux masonry surface

-

Faux Brick

Range using faux masonry surface

-

CLICKBRICK masonry panels are designed to reduce costs and installation time.

Our finishes are easy to use and compliant with the New Zealand Building Code. Our entry-level faux products start at $285/m2.

And when only real will do, our high-end architectural panels made of actual masonry will enhance your project.

CLICKBRICK specializes in high-end architectural masonry that is designed to reduce project costs and installation time. Our finishes are applied like weatherboards, making them easy to use, and our panels comply with the New Zealand Building Code.

Our entry-level products, which include thin faux finishes, start at just $285 per m2. For our more discerning customers, we also offer prefabricated panels made of actual brick or natural stone, which can greatly enhance the look and value of your project.

Please send your project plans to sales@clickbrick.co.nz to see how CLICKBRICK can help with your project.

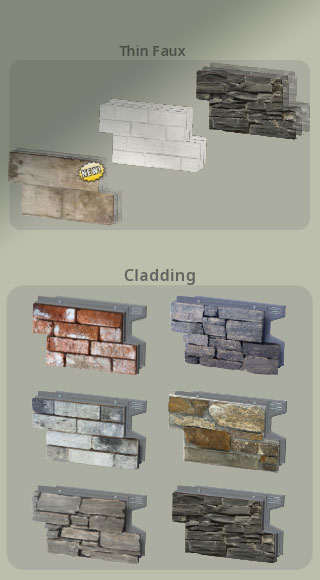

FAUX BRICK - FAUX CONCRETE - FAUX STONE

Our artificial finishes:

Our artificial finishes offer a practical alternative to traditional masonry thanks to the following features:

Our artificial finishes provide an exceptional alternative to real masonry with several compelling features:

| FORMAT | THICKNESS | FROM |

|---|---|---|

| Skins | 8mm | $180 /m2 |

| Panels | 40mm | $385 /m2 |

They are intentionally rustic to embody the character needed to offset the plainness of the white paint colour and look identical to the real thing.

This product is used externally for wall cladding, chimneys, and columns and internally for fireplaces and feature walls.

The exquisite light grey tones of Shuttered Concrete have sparked a renaissance in architectural brutalism.

Our CLICKBRICK products provide a lightweight and cost-effective alternative to real poured-in-place concrete, without compromising appearance or durability.

This versatile product offers endless possibilities to elevate your design. Externally, it's perfect for wall cladding, chimneys, and columns, while internally, it brings a touch of modern luxury to fireplaces and feature walls. Clients have the power to redefine the boundaries of architectural design and create something truly unique.

REAL BRICK - REAL STONE

Our red recycled clay brick exudes the charm of the "loft style" brick commonly found in American apartments, adding a rustic and warm touch. This brick boasts a valuable, time-honoured appearance, offering a sense of history and character that new bricks often lack.

Its character comes from the sedimentary layers typical to schist.

Recessed black pointing separates the individual stones which we place close together.

Our Strata Grey schist veneer panels, with their enduring appeal, bring a touch of timeless elegance to any project. Often used as a feature or textural break, they are perfect for wall cladding, chimneys, and columns. Internally, they add a touch of modern luxury to fireplaces and feature walls, ensuring the longevity and permanence of your design.

Taupe Stone is our premium product. Joint sizes are typically 25-30mm and is finished on site.

Below we highlight what CLICKBRICK can offer you or your business.

Manufactured housing companies use CLICKBRICK for stone and brick cladding (see photo). This off-site solution does away with the expensive footings required by traditional masonry and brings in many other benefits, like off-site consenting and alleviating the need for costly sub-trades.

CLICKBRICK is suited to pre-fabricators of all sizes, from tiny homes to large building companies. Easily add feature masonry. Either as a cladding or internal fit-out.

The building industry is changing quickly. Why not join our mailing list to keep up to date with our latest projects and developments?

Shopfitters choose CLICKBRICK over large format faux masonry products. Our products are easy for one person to carry and come in a range to suit all budgets. CLICKBRICK users can gain an advantage over their peers by reducing labour, waste, and build times.

CLICKBRICK differences:

Contact us now to learn how CLICKBRICK can help your next fit-out

More than just brick, our product selection is made right here in New Zealand for our local architecture.

Our modern manufacturing process uses precise dimensions and constraints. It requires more of loose masonry, resulting in higher-quality, more refined and uniquely curated finishes.

Our offering:

See our range of stunning products.

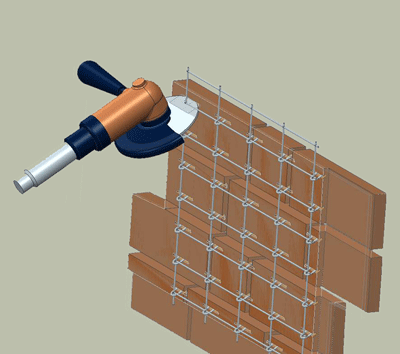

CLICKBRICK is manufactured to mitigate failures and post-sale margin erosion. We manufacture masonry to not fall off. This fact is perhaps the most compelling reason for using CLICKBRICK, especially in earthquake zones where even traditional brick has failed.

During manufacture, we pin masonry pieces into each panel (Figure 4.0). Then CLICKBRICK panels are mechanically fixed to the structural wall by SPAX washer-head screws.

Figure 4.0

Don't come undone during your 50-year legal obligation. Have your franchisees use CLICKBRICK.

CLICKBRICK does not require a constructed cavity like adhered masonry veneer. When assembled, our CLICKBRICK panels form a their own vapour plane at the back of the panels enabeling structures to breath.

Builders attach CLICKBRICK with a sheeting tool. No masons or sub-trades are required, giving you better project control.

Interested? Call us today to discuss.